適用范圍:

Scope of application:

?

適用于食品、藥片鋁塑包裝材料及包裝廠家的鋁塑邊角料、各種鋁塑復合材料的鋁與塑料的物理分離。

It is applicable to the physical separation of aluminum and plastics in food, tablet aluminum-plastic packaging materials, aluminum-plastic scraps and all kinds of aluminum-plastic composite materials of packaging manufacturers.

?

結(jié)構(gòu)特點:

Structural feature:

?

1.整套流水線采用PLC智能化編程自動控制與人機界面觸摸屏,使整條生產(chǎn)線均勻進料,協(xié)調(diào)工作。

1. The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2.結(jié)構(gòu)緊湊,布局合理,性能穩(wěn)定,粉碎設(shè)備降噪處理。

2. Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3.破碎與粉碎部分采用循環(huán)水制冷機降溫,不會因為設(shè)備長時間工作導致溫度升高而使塑料熔融或變色。

3. The crushing and grinding parts are cooled by a circulating water cooling machine, which does not melt or discolor the plastic because of the high temperature after long operation of the equipment.

4.采用物理破碎、粉碎、靜電分選方法將鋁與塑料分離,屬于環(huán)保型分離設(shè)備,替代了原來的化學藥劑鋁塑分離。

4. It adopts physical crushing, grinding and electrostatic separation method to separate the aluminum and plastic and is an environmentally friendly separation equipment which has replaced the original chemical pharmacy aluminum-plastic separation.

5.整套生產(chǎn)線配有脈沖除塵設(shè)備,凈化了工作空間。

5. The entire production line is equipped with pulse dust removal equipment, thus purifying the work space.

6.鋁塑分選純度高可以達到99.9%以上。

6. The highest purity of aluminum plastic sorting?purity?can reach more than 99.9%.

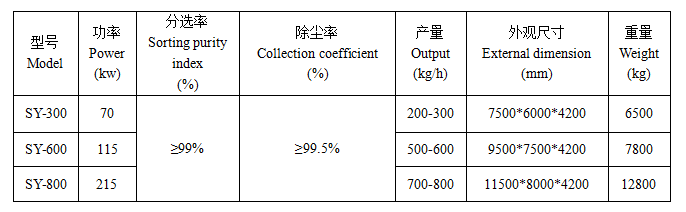

7.根據(jù)客戶產(chǎn)量需求可以定制設(shè)備。

7. Equipment can be customized according to customers' output demand.?

咨詢熱線

微信掃一掃